In the project before the final surface was assigned, our team (team 4) began the two week duration with some really fertile ideas during the brainstorming session. We all aligned on the premise that our surface would enable the use of natural sunlight without going through another medium-i.e. turning to battery power. Throughout the first week we met on 3 different occasions without building much, but the idea of a shading/light regulating device that would attach the the facade of the building seemed to interest the majority of group members.

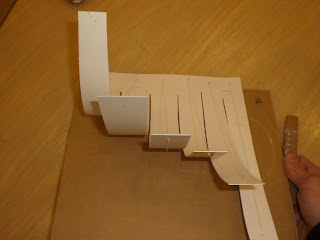

One of the first decisions came with the movement of the device and it became something we knew was achievable with stepper/servo motors and also something that Z had found to be a very real and unique bimetallic strip that is currently being tested. Afraid of going to far without truly refining what it was this surface did, we hit a road block by trying to decipher the why. For two more meetings our group sat idle trying to figure out how this might interact with sunlight/skyscrapers/convection/city dwellers. After more inconclusiveness we decided to learn by making and created a pretty decent mockup.

As far as group work goes, the entire group came together during the end of the two weeks. The first week was incredibly different to get everyone together at once and each meeting our group was missing a few links, this caused periods of catching up during the next meetings. However in the end, everyone really sought to step up and help with something they had or had not done before. I was especially impressed at those who jumped at the chance to take digital project responsibilities without much training or previous knowledge. In the end we had built a surface that operated in the manner in which we thought the "real life" materials might respond if embedded into the facade of the building. We had talked quite a bit about the presentation and representation of the project, and hoped that interesting enough ideas would supplant our inability to gain access to bimetallic strips.

Julian Bleecker spoke very long about the production of things being a precursor to the discovery of purpose and usefulness. Team 3 was able utilize the Hoberman Sphere and created a very intricate two dimensional one but in the end admittedly found little purpose in their design-which in a sense was what Julian seemed to be articulating as his prime way of working. Our team seemed to work similarly in that we discovered this movement from a set of materials and immediately made it our project. Nearly half way through we hit a road block and all working and making stopped in order to find out why and attribute it to something that would be helpful. In the end I believe this period of stopping hurt us in the way that our surface was not nearly as refined or cleanly/interestingly executed as the other groups'. We could talk about it a bit more in application but I begin to wonder about the end result if the making had not stopped nearly half way through. If we had constructed multiple iterations and explored extremes of this set-up, might we have found a better and more logical application?